Automatic Aluminum Foil Tray Stacker

Control system

Setting system: SIEMENS

Inverter: Janpan Sanken

AC Contactor: Schneider

Controlling button switch: Schneider

Double Solenoid Valve: Taco

Inverter of Motor and Feeder: Sanken

Exchange communication device:MOSA

1.The motor is changed from 3000 watts to 4000 watts, and a frequency converter is added to adjust the wattage and power of three gears of thin, medium and thick materials

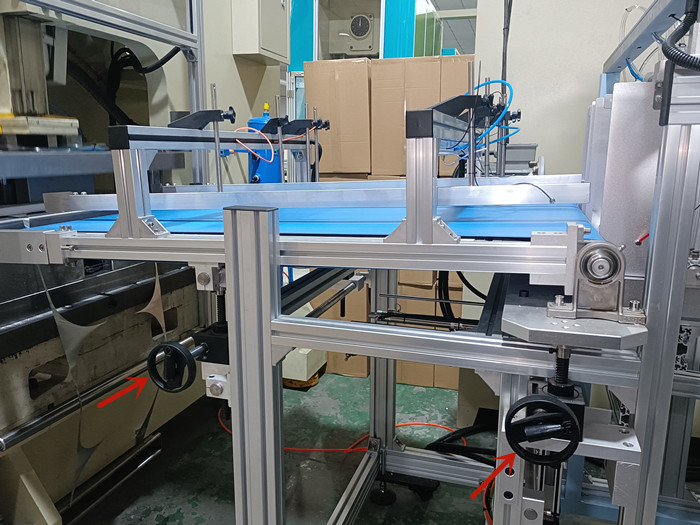

The current 1720mm belt is easy to hurt the main shaft, the belt is changed to 1240mm. Do before and after lifting, low before and high after climbing mode. Thus the aluminium foil container stacker can work smooth.

2. The side baffle of the aluminium foil container stacker collection station is lengthened to protect the stacking effect of products and not to scatter.

The side baffle of the collection station is lengthened to protect the automatic stacking system effect of products and not to scatter.

The front blowing without delay, accelerate the meal box from the conveyor belt to the collection platform; After blowing delay 0.2-0.3s (specific to the size and weight of the meal box), guide the meal box automatic tray stacker, compaction.