| Material | Stainless Steel |

| Treatment | High-temperature heat |

| Application | Machinery & hardware |

| Usage | Making Aluminum foil container |

| name | Aluminium foil container mould |

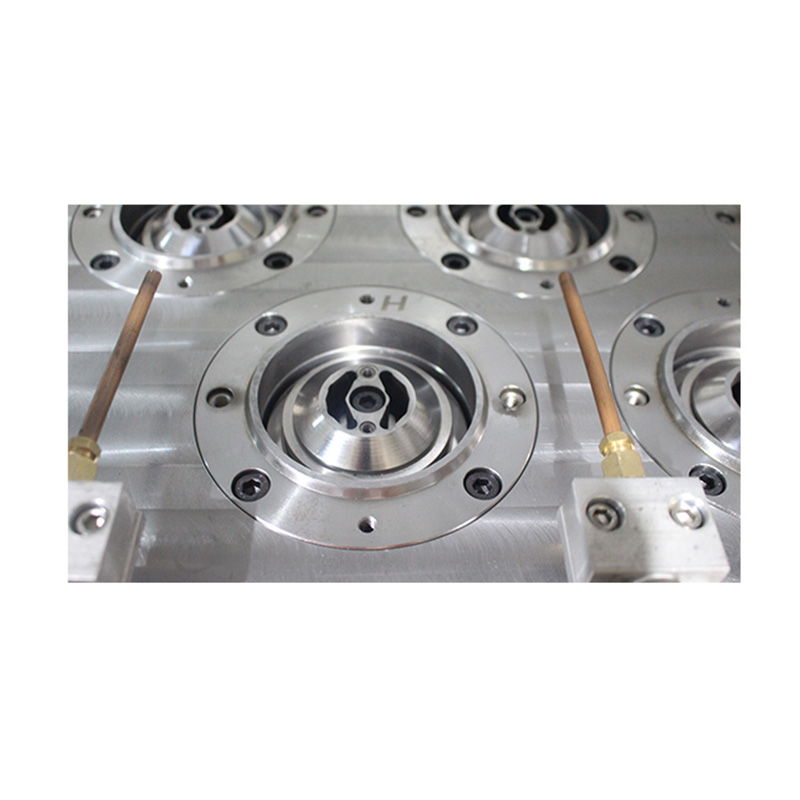

| Cavity | Single and Multi- Cavities |

| Type | Smooth/wrinkle-wall container mould |

| Style | One compartment or multi-compartment |

| Rim | Full/ IVC/ Folded / Reverse rim |

| Guarantee | One year |

| After-sales Service Provided: Engineers available to service machinery overseas | |

1.The moulds that we design and produce are suitable for almost every kind of machine or press.

2. We produce mould with the best quality steel in China. And some main mould areas are made high-temperature heat treatment for proper hadness, which ensure moulds are in great quality and long life.

3. To meet customers’ different requirement, we design and manufacture the mould in several rims, such as G rim, L rim, H rim, and IVC etc.

4. We can design and produce the mould in multi-cavities, no matter it is one compartment container or multi-compartments container.

5. In order to save foil material cost, we has innovated “zero- web" moulds. This kind of mould will reduce lots of foil scrap.

3.1 Specification: single cavity mould, 2, 3, 4, 5 cavities, ect.

3.2 Brand: CHOCTAEK.

3.3 Place of Origin: Foshan, China.

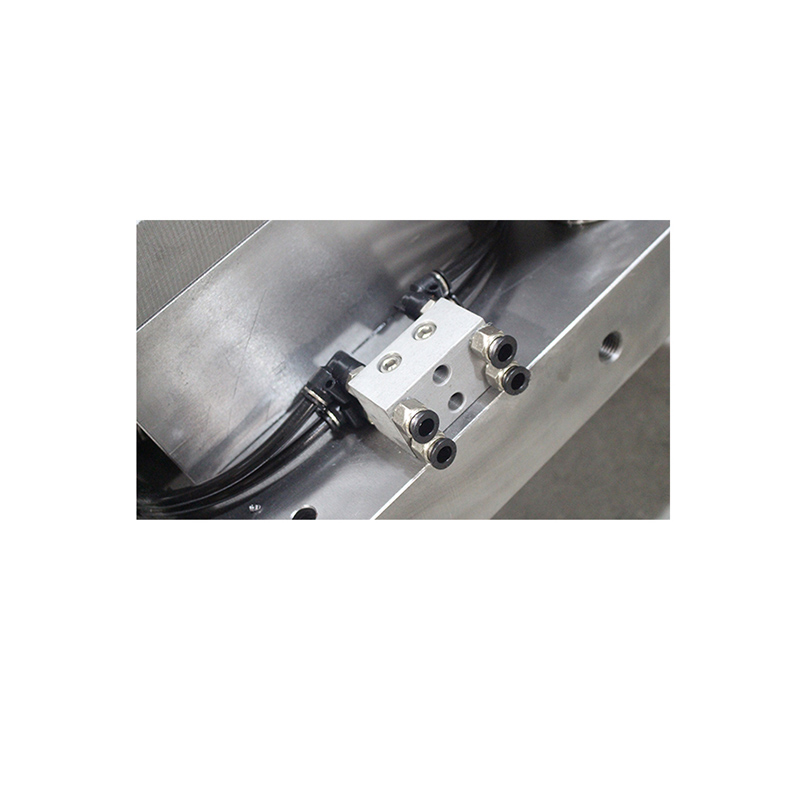

3.4 Driven Type: Pneumatic.

3.5 Packaging Type: packed in seaworthy wooden case.

3.6 Application: To produce aluminium foil containers for food package.

Packaging type: Packed in wooden case.

Port of shipment: Guangzhou, Shenzhen, Chinese Port.

We manufacture high technology mould for many customers. We can produce several different rim configurations to meet the customer’s requirements including G rim, L rim, IVC and so on.

We build up all of our mould with the high quality material. Flow areas are heat treated for proper hardness. These quality controls ensure reliable moulds for long life.

CHOCTAEK imported 8 CNC machines which is equipped with advance control panel and system. We also has a very experienced technician team who could operate and control the CNC machines skillfully (10 person work 24 hours).

CHOCTAEK imported three WEDM- LS machines from Japan (Sodick), which is equipped with advance control panel and system.

CHOCTAEK imported four Grinding Machines from Taiwan, which is equipped with advance control panel and system. Our Grinding Machines use high- speed rotating grinding wheel to grind and process.

We also have a very experienced technician term who could operate and control the Grinding Machines skillfully.

With these three machines, we could process the mould parts in high precision, high quality and working efficiency.

Therefore, we will increase our mould quality to a high level & standard, and even will speed up our mould production.